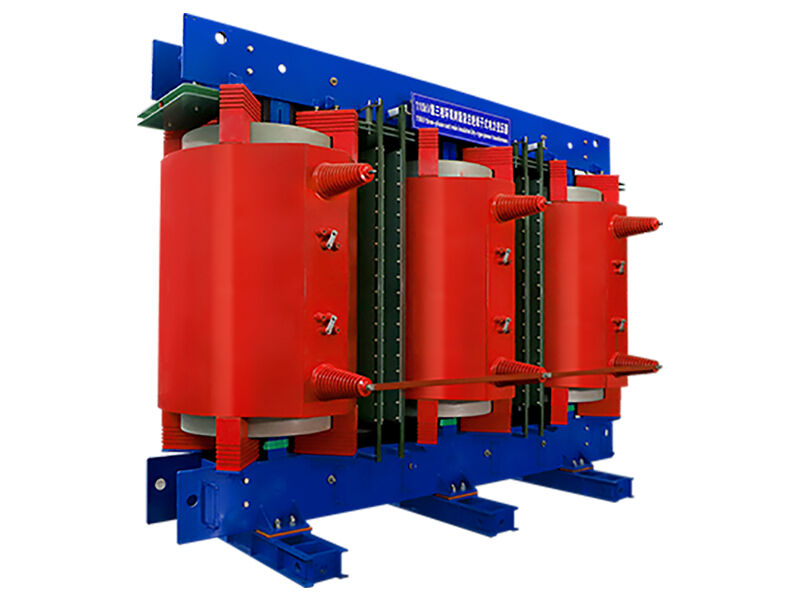

Dry-type transformers are electrical transformers that utilize air or solid insulation for cooling and insulation purposes, eliminating the reliance on liquid mediums such as oil. In recent years, these transformers have attracted significant attention across the power distribution industry. By combining enhanced safety, reliability, and environmental benefits, they present a compelling advantage over traditional oil-immersed transformers, establishing themselves as the preferred choice for a wide range of modern applications.

1. Safety as the Foremost Priority

The primary advantage of dry-type transformers lies in their inherent safety. Unlike oil-immersed units, which require large quantities of flammable mineral oil for insulation and cooling, dry-type transformers operate using air or solid resin-based insulation systems. This fundamental design eliminates the risks associated with oil leaks, spills, and potential fires. Consequently, they are exceptionally well-suited for indoor installations and locations where fire safety is non-negotiable. Such environments include high-rise buildings, hospitals, schools, shopping malls, airports, metro stations, and other densely populated commercial complexes, where they provide critical power distribution with minimal hazard.

2. Environmental Sustainability

The absence of insulating oil makes dry-type transformers an environmentally responsible choice. They completely remove the threat of soil or water contamination from oil leaks, a significant concern with oil-filled counterparts, especially in ecologically sensitive areas. Furthermore, their simplified construction and "maintenance-free" characteristics—requiring no periodic oil testing, filtration, or replacement—translate into reduced resource consumption throughout their operational lifecycle. This alignment with green manufacturing principles and sustainable energy initiatives positions dry-type transformers as a key component in building eco-friendly power infrastructure.

3. Minimal Maintenance Requirements

Operational efficiency is greatly enhanced by the reduced maintenance needs of dry-type transformers. Oil-immersed transformers demand a rigorous maintenance regimen, including regular oil sampling for dissolved gas analysis (DGA), moisture control, leak inspections, and oil purification or replacement. These activities necessitate specialized tools, skilled personnel, and potential downtime. In contrast, dry-type transformers, free from oil-related complications, primarily require basic upkeep such as visual inspections, cleaning of ventilation ducts, and ensuring the proper operation of cooling fans and temperature control systems. This leads to lower lifetime ownership costs, less operational disruption, and consistently dependable performance.

4. Exceptional Versatility and Application Range

Dry-type transformers demonstrate remarkable adaptability across diverse settings. Their robust design, often housed in IP (Ingress Protection) rated enclosures, allows them to perform reliably in challenging conditions exposed to dust, moisture, humidity, and corrosive atmospheres. This versatility enables their seamless integration into a broad spectrum of applications:

● Mission-Critical Facilities: Data centers, telecommunications hubs, and financial institutions.

● Industrial Plants: Manufacturing facilities, chemical plants, and mining operations.

● Renewable Energy: Wind farms and solar power stations.

● Commercial and Public Infrastructure: Office buildings, universities, and hospitals.

Their compact design and flexibility in placement (without the need for containment pits or oil spill protection systems) further simplify installation and save valuable space.

5. Enhanced Performance and Reliability

Modern dry-type transformers, particularly those employing advanced epoxy resin vacuum casting technology, offer superior performance characteristics. The process encapsulates the windings in a solid, monolithic insulation block that provides excellent resistance to moisture, chemicals, and mechanical stresses. This construction enhances their short-circuit strength and allows for stable operation in high-humidity environments, often without requiring auxiliary dehumidification equipment. Additionally, modern designs focus on improving energy efficiency and reducing audible noise levels, making them suitable for installations where low environmental impact is desired.

Conclusion: A Forward-Looking Investment in Power Distribution

The global shift towards safer, cleaner, and more resilient electrical systems is unmistakably driving the growing demand for dry-type transformers. Their synergistic blend of inherent safety, environmental sustainability, low maintenance, and robust performance makes them a technologically advanced and economically sound investment for the future. As material science and smart monitoring technologies continue to evolve, dry-type transformers are poised to play an even more pivotal role in shaping the intelligent and sustainable power grids of tomorrow.