In an ambitious move to align with China's national "Smart Manufacturing" strategy and to solidify its position as an industry frontrunner, Jiangsu Ryan Electric Co., Ltd. has successfully completed a full-scale technological transformation of its Energy Transformer Workshop. This landmark initiative marks a significant leap forward in the company's journey towards intelligent, high-end manufacturing, fundamentally enhancing production efficiency, product quality, and environmental sustainability.

Driving Forces Behind the Upgrade: Strategy and Market Vision

Established in 2007, Jiangsu Ryan Electric has grown into a renowned high-tech enterprise specializing in power transmission and distribution equipment. With an impressive annual production capacity exceeding 20,000 MVA and a diverse portfolio of over 20 product series—including dry-type transformers, oil-immersed transformers, and various pad-mounted transformers—Ryan Electric serves critical sectors such as Electric Power, Data Centers, New Energy, and Petrochemical industries. The decision to undertake this comprehensive workshop upgrade stems from a forward-looking strategy to not only meet escalating market demands but to anticipate them. By leveraging proprietary engineering expertise and integrating global innovations from strategic partners like Eaton, the company is poised to deliver intelligent energy solutions that consistently surpass stringent international standards. This upgrade is a tangible manifestation of its commitment to operational excellence and technological leadership.

A Deep Dive into the Core Upgrades: Precision, Automation, and Intelligence

The transformation focused intensively on core manufacturing processes, introducing state-of-the-art equipment and intelligent management systems designed to set a new benchmark in transformer production.

1. Transformer Testing Station: Authoritative Certification, Uncompromising Quality Assurance

The newly modernized Transformer Testing Station stands as a cornerstone of this upgrade. Its accreditation by the China National Accreditation Service (CNAS) grants its test reports international recognition and mutual acceptance, a critical asset for global market access. This facility is equipped to perform a comprehensive suite of performance tests, including:

● No-load loss measurement: Precisely quantifying core energy losses to ensure optimal efficiency.

● Lightning impulse testing: Simulating and verifying the transformer's resilience against high-voltage surges from lightning strikes.

● Short-circuit impedance detection: Assessing the ability to withstand short-circuit forces, crucial for grid stability.

● Voltage and current endurance verification: Ensuring reliable operation under specified electrical stresses.

Every test is rigorously conducted in accordance with Chinese National Standards (GB/T), providing irrefutable evidence of quality and reliability for every unit leaving the factory.

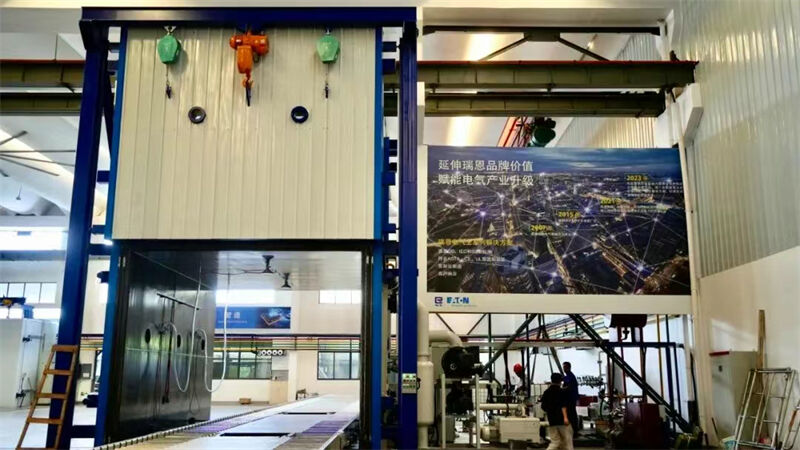

2. Variable Pressure Vacuum Drying: Advanced Moisture Elimination for Enhanced Stability

Moisture is a primary adversary of transformer longevity and reliability. The new, fully automated Variable Pressure Vacuum Drying System represents a paradigm shift from conventional methods. This sophisticated process employs intelligent temperature control and multi-stage dehumidification cycles within a dynamically adjusted vacuum environment. This ensures the complete and deep removal of moisture from the innermost layers of the transformer core and insulation materials. The result is a significant enhancement in the dielectric strength of the insulation system, a drastic reduction in the risk of partial discharges, and a substantial extension of the transformer's operational lifespan, ensuring steadfast performance in the most demanding applications.

3. Vacuum Oil Filling Equipment: Precision Engineering for Flawless Insulation

The introduction of high-precision Vacuum Oil Filling Equipment addresses another critical phase in transformer assembly. This system creates and maintains an optimal vacuum environment before and during the oil-filling process. By doing so, it completely eliminates the formation of air bubbles and prevents the introduction of impurities during the impregnation of the insulation oil. This meticulous control is vital for maximizing the transformer's dielectric strength and overall electrical integrity, directly translating into superior operational reliability and a marked reduction in potential field failures.

Strategic Impact: Delivering Tangible Value Across the Board

The comprehensive overhaul of the Energy Transformer Workshop yields multifaceted benefits that extend beyond the factory floor:

● Unprecedented Quality Enhancement: The synergy between the CNAS-certified independent testing authority and the fully integrated vacuum processing techniques (drying and oil-filling) creates an uncompromising quality control ecosystem. This robust framework significantly elevates product integrity and drives down product failure rates, delivering unparalleled peace of mind to customers.

● Significant Efficiency and Productivity Gains: The widespread adoption of automation and intelligent systems across production stages has streamlined workflows, minimized manual intervention, and optimized process cycles. This acceleration in production throughput enables faster order fulfillment and empowers customers to meet their project deadlines with greater confidence.

● Commitment to Green and Sustainable Manufacturing: Ryan Electric has embedded environmental responsibility into its upgraded processes. The fully sealed drying and oil-filling systems effectively contain all volatiles and prevent any release of pollutants into the environment, achieving the goal of zero industrial emissions from these critical operations. This aligns with global sustainability mandates and reflects the company's role as a responsible corporate citizen.

Looking Ahead: A Future Forged by Continuous Innovation

The successful upgrade of the Energy Transformer Workshop is not an endpoint, but a pivotal milestone in Ryan Electric's continuous improvement journey. It solidifies the foundation for tomorrow's innovations. Looking forward, Ryan Electric remains steadfast in its dedication to pioneering cutting-edge technologies, refining manufacturing processes, and exploring new frontiers in transformer design and functionality. The company is committed to being a trusted partner for its global clientele, providing ever-safer, more efficient, reliable, and environmentally sound transformer solutions that power progress and enable a sustainable energy future.