Up to 44kV Up to 10000kVA Unit Substation Transformer

Voltage: Up to 44 kV

Rated Power: Up to 10000 kVA

Applications: Urban areas, Commercial buildings, Industrial plants, Infrastructure projects, Renewable energy stations, Rural power distribution, etc.

Production Standards: GB, IEC, IEEE, UL, CE, ASTA

- Overview

- Description

- Applications

- Advantages

- Production Process

- Certificates

- FAQ

- Recommended Products

Overview

| Voltage: | Up to 44 kV |

| Rated Power: | Up to 10000 kVA |

| Primary Voltage: | 10 kV, 11 kV, 20 kV, 22 kV, 33 kV, 35 kV, 44 kV |

| Secondary Voltage: | 230 V, 240 V, 400 V, 415 V, 480 V, 600 V, 690 V |

| Core material: | Copper/Aluminum |

| Cooling Methods: | ONAN/ONAF/KNAN/KNAF |

| Transformer Oils: | Mineral oil/FR3/Silicone oil |

| Operational Environment: | Heat/Cold/Earthquake/Corrosive |

| OEM & ODM: | Color & Logo |

Description

Our 10 kV–44 kV unit substation transformers provide a compact, integrated solution for safe, reliable, and efficient power distribution. Designed with high-quality transformers, medium-voltage switchgear, and low-voltage distribution panels all in a single factory-assembled unit, they offer a space-saving, maintenance-free, and cost-effective alternative to traditional substations.

Engineered with durable cores, optimized winding structures, and advanced insulation materials, these transformers deliver low loss, high efficiency, low noise, and excellent short-circuit resistance, ensuring stable operation in demanding environments. The robust enclosure protects the equipment from harsh conditions, making it ideal for both indoor and outdoor installations.

Applications

Unit substation transformers are widely used in residential and commercial areas, industrial facilities, hospitals, airports, railway stations, tunnels, renewable energy projects, and rural electrification, providing safe and reliable power where compact design and quick installation are critical.

Advantages

• Compact & Space-Saving: Integrated design reduces footprint, ideal for urban and industrial environments.

• High Reliability & Safety: Durable construction and advanced insulation materials ensure stable operation and protection.

• Low Loss & High Efficiency: Optimized core and winding design reduce energy losses and operating costs.

• Low Noise & Maintenance-Free: Engineered for quiet operation and long-term, maintenance-free performance.

• Flexible Installation: Suitable for indoor or outdoor installation, near load centers for reduced distribution costs.

• Versatile Applications: Perfect for commercial, industrial, infrastructure, and renewable energy projects.

Production Process

Production Process of Oil Type Transformers

Finished Transformer

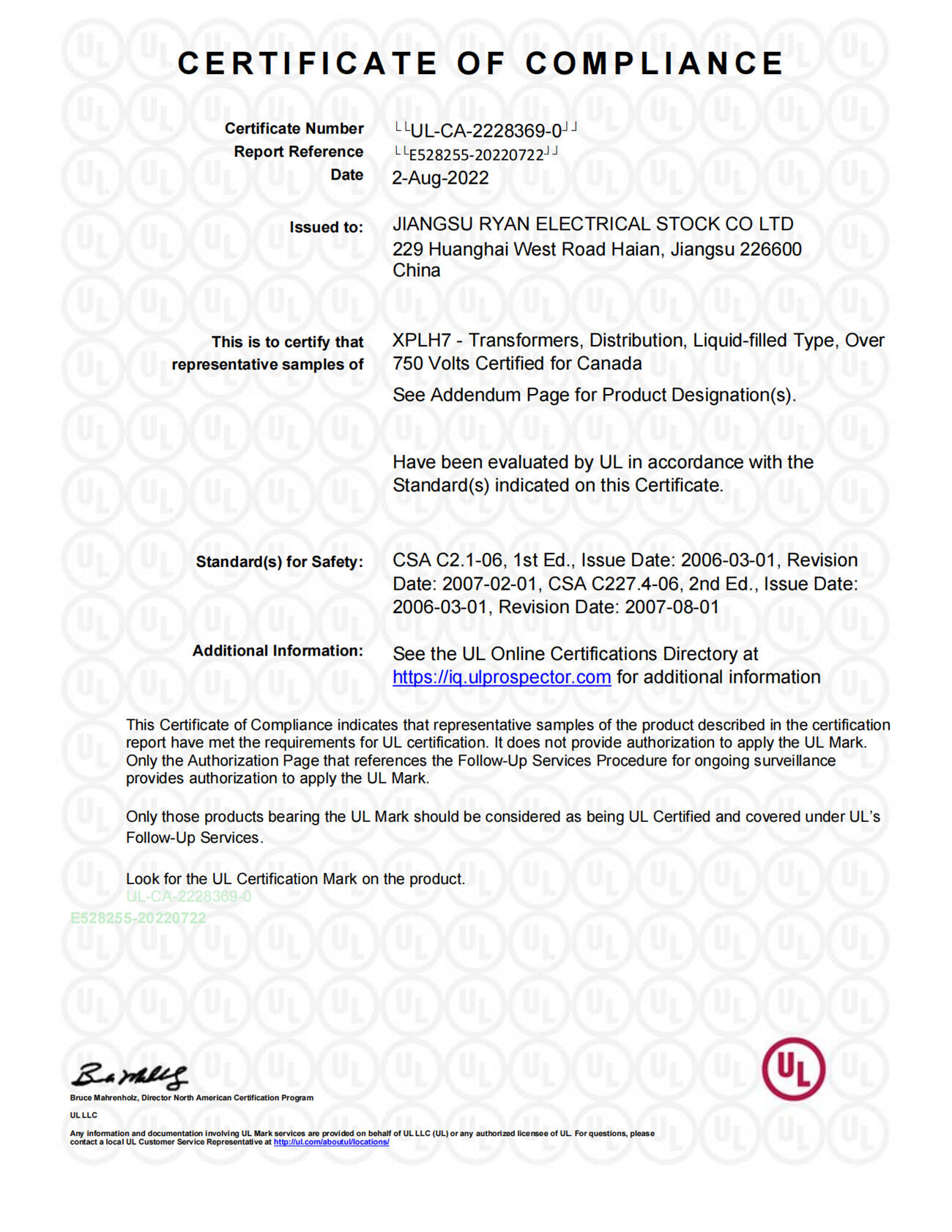

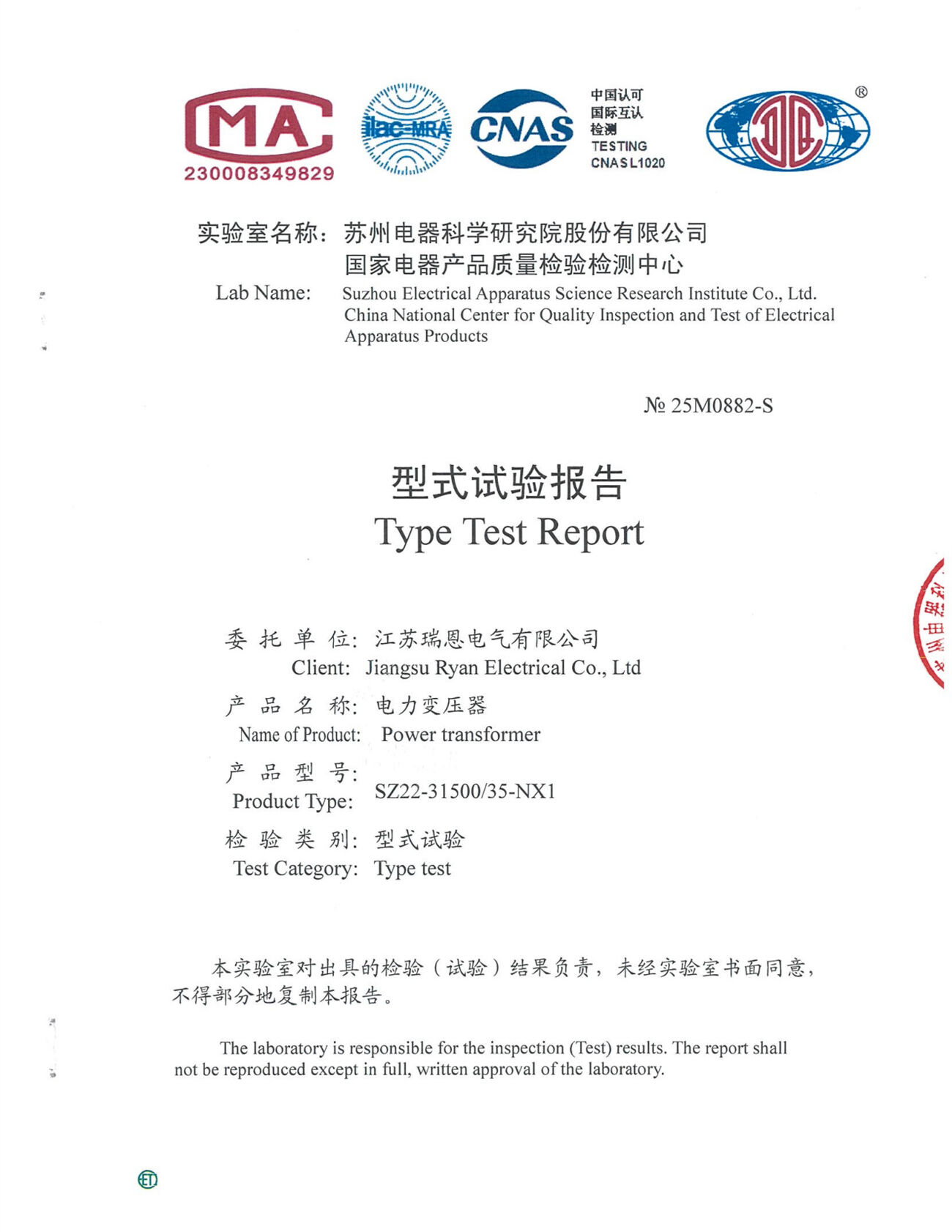

Certificates

FAQ

Q: Who are we?

A: As a joint venture with Eaton in 2023, Ryan Electric is a leading and professional manufacturer of cast resin transformer, oil immersed transformer, pad mounted transformers and every kinds of substations since 2007.

Q: Why should you buy from us not from other suppliers?

A: Our company holds international certifications including UL/CSA/IEEE/IEC/EUR and DEKRA. Also obtained CNAS certification for testing center. We are key partners to world-renowned enterprises such as Microsoft, Amazon, TBEA, and State Grid, providing reliable, secure, and stable power equipment and services.

Q: OEM and ODM available?

A: Yes, we supply customized solution to clients.

Q: What are preferred Terms of Payment and delivery?

A: T/T, L/C, EXW, FCA, FOB, CFR, CIF, DDP

Q: How long is the warranty of your product?

A: We offer a standard warranty of 12 to 24 months from the date of commissioning or shipment, depending on the product line.

Q: How long is your production time?

A: Lead times vary based on product complexity, customization, and order volume. Standard product lead times range from 4 to 12 weeks. With a monthly production capability of 2,000 units, our annual output reaches up to 20,000 MVA.

Q: After-sales service

A: Our support services include:

-Installation guidance & technical support available on-site or online.

-30-minute response time to any customer inquiry.

-2-hour commitment to provide a preliminary solution.

-48-hour on-site dispatch if required.

Q: Want to join our network as a branded partner?

A: Yes, we welcome potential partners! We are committed to supporting our agents with comprehensive business, technical, and after-sales support. To ensure your success, we implement a market protection strategy and work closely with you to develop the global market, fostering a truly win-win partnership.

Q: What are the primary applications of our transformers?

A: Our transformers deliver specialized solutions for a range of key sectors: Electric Power, Data Center, New Energy, Petrochemical Industry and Construction, among others.